definition vickers hardness test|vickers hardness test pdf : Brand If HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm , then the tensile strength (in MPa) of the material can be approximated as σu ≈ HV/c , where c is a constant determined by yield strength, Poisson's ratio, work-hardening . See more Ler We Got Ourselves Stuck Inside an Adult Fantasy Novel - Mangá (PT-BR) Há um limite para o que se pode esperar de sua amiga gritando sobre mais um romance clichê de fantasia. Mas o maior clichê de todos acontece quando Jiwon e Yein reencarnam com Sihyeon na história exata pela qual sua amiga é tão obcecada! Embora Deus as tenha .

{plog:ftitle_list}

3 de mar. de 2010 · Album: Pac-Man FeverArtist: Jerry Buckner & Gary GarciaSong: Pac-Man FeverThis is the first track from side A of the album.Each song from this album is about.

vickers hardness test theory

tetrachromatic vision test hard

vickers hardness test procedure

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size . See moreIt was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter . See moreWhen doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work . See more

To convert the Vickers hardness number to SI units the hardness number in kilograms-force per square millimeter (kgf/mm ) has to be multiplied with the standard gravity, $${\displaystyle g_{0}}$$, to get the hardness in MPa (N/mm ) and furthermore divided . See moreIf HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm , then the tensile strength (in MPa) of the material can be approximated as σu ≈ HV/c , where c is a constant determined by yield strength, Poisson's ratio, work-hardening . See moreThe fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds. However, on the aircraft flying Partnair Flight 394 the pins were later . See more

• Indentation hardness• Leeb Rebound Hardness Test• Hardness comparison• Knoop hardness test See more• Meyers and Chawla (1999). "Section 3.8". Mechanical Behavior of Materials. Prentice Hall, Inc.• ASTM E92: Standard method for Vickers hardness of metallic materials (withdrawn and replaced by E384-10e2) See more

texas music teacher certification test hard to pass

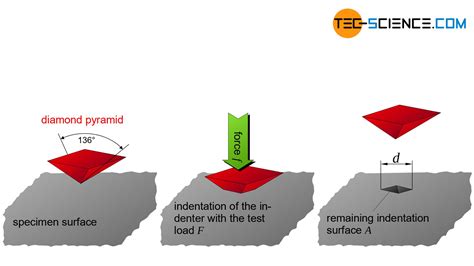

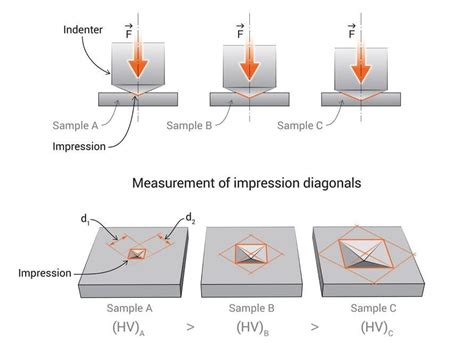

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .Definition. The Vickers hardness test is a method used to measure the hardness of materials, specifically metals, by indenting the material with a diamond pyramid under a specific load.The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it . What is the Vickers Hardness Test? This procedure was developed in 1921 by Robert L. Smith and George E. Sandland during their work at Vickers Ltd. It was meant to be an alternative to the already-established .definition of the vickers hardness test The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials.

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads .

Vickers Hardness (Mean±SD) Empty Cell: Before grinding After grinding; Curtis et al., 2006: Lava frame: Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load (9.807 N) over 15 s to induce a diamond-shaped indent. The size of .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can .

Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: . In-depth definition of hardness testing involves evaluating the hardness level of a material by measuring the depth or area of indentation left by an indenter of a specific shape, applied with a specific force for a . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements. Fig. 1 illustrates a Rockwell hardness test cycle, where the applied force during the test cycle is shown at the top portion of the figure, and the corresponding indentation behavior is shown below. The Rockwell hardness test applies two levels of force to the indenter with periods of the force being held constant (dwell times) and the indentation depth is measured twice.Definition. The Vickers hardness test is a method used to measure the hardness of materials, specifically metals, by indenting the material with a diamond pyramid under a specific load. This test provides a hardness value that correlates with the material's resistance to deformation and wear, linking it to surface hardness and elasticity, which .

The equation based definition of hardness is the pressure applied over the contact area between the indenter and the material being tested. As a result hardness values are typically reported in units of pressure, although this is only a "true" pressure if the indenter and surface interface is perfectly flat. . Vickers hardness test (HV .

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).The Vickers hardness test can be a macro or micro hardness test as it can bear a load up to 50 kg. The process of the Vicker hardness test is the same as the Knoop test but the indenter used hare is a square-based diamond pyramid indenter. Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . Therefore, the traditional definition of hardness will yield an infinite value, making it impossible to obtain the true hardness value of the sample. Furthermore, the measurement ranges of the two methods are different .

The meaning of VICKERS HARDNESS TEST is an indentation hardness test for metals in which a 136-degree diamond pyramid is pressed into the surface of the metal being tested by a load of 5 to 120 kilograms.The Vickers Test is a method for measuring the hardness of materials, using a diamond pyramid indenter to create an impression on the material's surface. This test is significant in material testing and characterization as it provides valuable insights into a material's mechanical properties, allowing for comparisons between different materials and informing decisions about .

How Do Hardness Testing Loads Work? Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below:

Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be .

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's hardness. The Vickers test employs a pyramid-shaped diamond indenter with a square base angle of 136 degrees. This indenter is pressed into the material under a known . For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.Hardness Testing. G. Sundararajan, M. Roy, in Encyclopedia of Materials: Science and Technology, 2001. 2.2 Ultrasonic Microhardness Testing. In ultrasonic microhardness testing, a Vickers diamond is attached to one end of a magnetostrictive metal rod. The metal rod is excited to its natural frequency by a piezo electric converter. The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. Although the concept of using one test method to cover a wide range of materials hasn’t changed much in the last 90 years, upgrades to the equipment used to perform the test have expanded its use and accuracy. The Vickers hardness number is the load (test .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance .Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but .

The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

ClickVita - Entrega de relatórios. Simples é ter tudo a um cliq.

definition vickers hardness test|vickers hardness test pdf